- Description

- Shipping and Refund

- Reviews

Fits:

1996-2000 Civic

- 12.9 Grade heat treated shot peened flywheel Bolts

- High-quality bolts and washers

Basic installation note and pictures listed below.

need basic hand tools and torque wrench

cherry picker

grinder

cut off wheel

fluids

4x OEM honda engine to transmission alignment dowel pins

LOCTITE blue 242

SHIPPING: Shipping is Free to lower 48 states of the USA, including a tracking number.

SHIPPING SERVICE FOR P.O BOX SHIPMENT AND ANY AFO AND APO ADDRESS $50

SHIPPING SERVICE FOR ALASKA HAWAII, PR AND GUAM AND OTHER U.S. VIRGIN ISLANDS $50

International orders please E-mail us for shipping quote: info@1320performance.com

Prepare the engine:

1. remove the small tab on the top of the h22 block picture below so the plate can sit flush with the engine.

2. insert 2 dowel pins into the engine one by the clutch slave cylinder (front of the engine and one in the rear) the rear dowel pin by the starter will need to be ground down so there's enough space for the starter bolt. (pic attached)

3. install the h2b plate onto the engine tight up all 4 countersunk bolts to 25ft lb that lock the plate on to the engine (picture below)

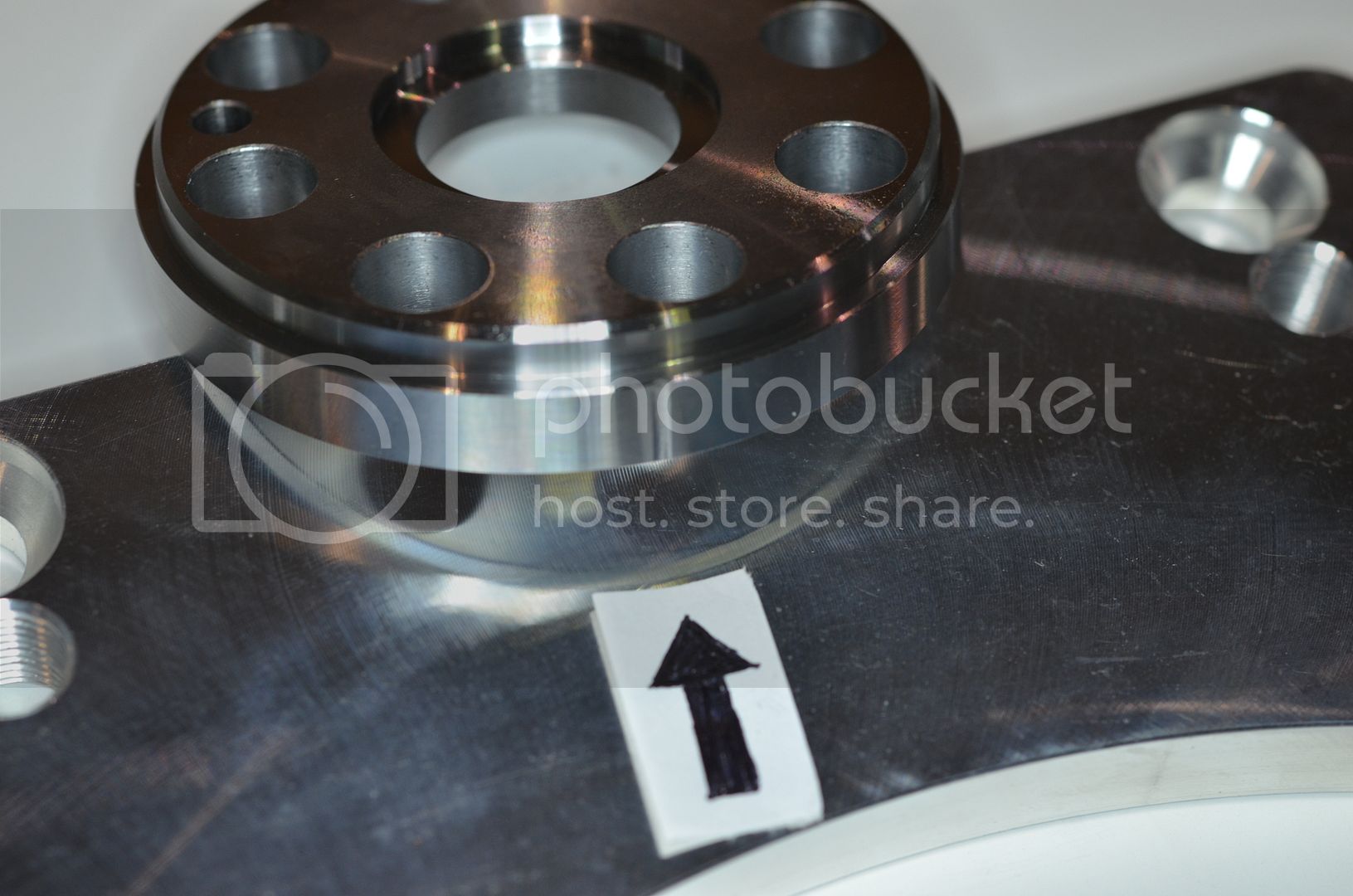

4. Install our stainless steel Crank shaft spacer. the spacer can only be installed one way just align the alignment pin on the crank shaft.

our crank shaft spacer includes a machined line indicating TDC. Use timing gun to adjust timing with this feature.

install your B series clutch and flywheel on to the engine.

There's hundreds of different flywheels on the market today some of them do not follow the OEM flywheel thickness under the head of the flywheel bolt for example, aluminum flywheels, twin or triple disk flywheels and more, so before install take a measurement, put the crankshaft spacer on to the back of the flywheel you are using insert the flywheel bolts and take a quick measure of the protruding part of the bolt it should be between .46 and .48 inches. if the protruding part is over .48 inches you should shorten the bolt and measure again before install. if the protruding part of the bolt is less than .46 inches you should resurface the face of the flywheels where the flywheel bolts is installed.

1. measure the bolts to make sure it's with in spec with the flywheel you are using.

2. clean the crankshaft thread with a M12x1.0mm bottom out tap. using compressed air to clean afterwards.

3. using LOCTITE blue 242 on all bolts to prevent bolt backing out due to vibration.

4. using Crisscross pattern and torque all bolts to 90 ft-lbs using a torque wrench. ( Do not use air impact)

5. bolts can to be reused for no more than 3 times due to bolt stretch

5. place the other 2 dowel pin onto the engine. Insert the 10mm starter bolt through the backside of the transmission case with the head of the bolt towards the h2b plate (picture below where the black arrow is that is where the starter bolt head will be staying in). (right below the arrow is where one of the dowel pin that was grind down) For the bolt to have enough clearance that's why in step #2 we have to grind down that dowel pin. The machined h2b plate have enough clearance to clear the bolt head (picture attached) IF YOU FORGOT TO INSERT THE STARTER BOLT YOU WILL HAVE TO REMOVE THE ENGINE FROM THE TRANSMISSION TO INSERT THE BOLT AGAIN.

6. Align and secure the engine to the transmission. Place 3x 60mm bolts 2 on the top one on the front of the transmission torque all 3 to 35ft lb.

Install the starter onto the transmission. an upper bolt of the starter torque to 30ft lb bottom nut torque to 35 ft-lb.

remove the dust cup on the OEM b series manual transmission intermediate shaft, insert the intermediate shaft on to the back of the transmission.

7. Install the intermediate shaft bracket.

take your time check for clearance. use your grinder and cut-off wheel and remove material little by little. the picture below.

8. Remove the timing belt cover install the engine mount bracket.

9. install the clutch slave cylinder spacer.

use a 1/4 drill bit open up the clutch slave cylinder mounting hole so the 2 bolts can be installed at a slight angle on the slave cylinder.

The slave cylinder will be mounted on the Billet spacer tighten the 2 bolts to 17 ft-lb